ChampFood International customer

23-06-2022

ChampFood International is a market leader in the worldwide mushroom industry. For that reason we are in contact with many renowned composters, mushroom growers and consultants.

Due to our international network we are familiar with the latest developments, trends and newly acquired knowledge. Frequently we asked our international contacts to share their experiences and knowledge in the ChampFood Internationals Newsletter with us.

This time we asked a valued customer of ChampFood International to put his business in the picture:

Dr.Kurade’s first generation family agribusiness, established in 1994. With two farms M/s. Zuari Foods & Farms P. Ltd. & M/s. Tropical Mushrooms (Goa) P. Ltd., one of the largest and oldest mushroom farms in India, since 30 years.

We learnt to grow without technical help from 5 rooms to 105 rooms now! From 500Kgs per day at 15% yield (weight of compost) to 20000 Kgs at 30% yield. That too using Sugarcane Bagasse all with Phase 2 and in growing bags!!

We had suffered major flood destruction of the farm in 2009-2010 from which we rose like a phoenix.

We have been in business since last 30 years and have seen the market evolve over the years. We have been growing mushrooms even before people could include this super food in their regular food cycle. India did not know how to eat/cook these vegetables! We have gained continuous and consistent customer base and thereafter the consumption has increased specially over last 10 years. Demand for the same expected to be ever increasing 10-15% year on year!

With two multi-facility farms in Goa spread over 1,20,000 sq mt with 2,70,000 sq ft of vertical growing area, presently with installed capacity of over 6000 tons annually (daily over 17,000 kgs!) of fresh mushrooms with sales and distribution all over Western and Southern India.

We now have 105 rooms with 4 rows of 7 level shelves. Monthly 55-60 batches of 50 tons green compost using Sugarcane bagasse which are filled in Phase 2 (30 tons post Phase 2), approximately 2 batches daily in bags. We get approximately 30% yield on compost weight basis.

Most raw material are procured within 1000 Km radius.

Main raw material being Sugarcane bagasse and Paddy Straw with Chicken Manure being the Nitrogen source. Supplement is negligible to reduce costs and most is locally sourced, though very few containers are imported annually. For casing soil, we use a mix of coconut dust and clay soil. Only Spawn used is imported from Netherland.

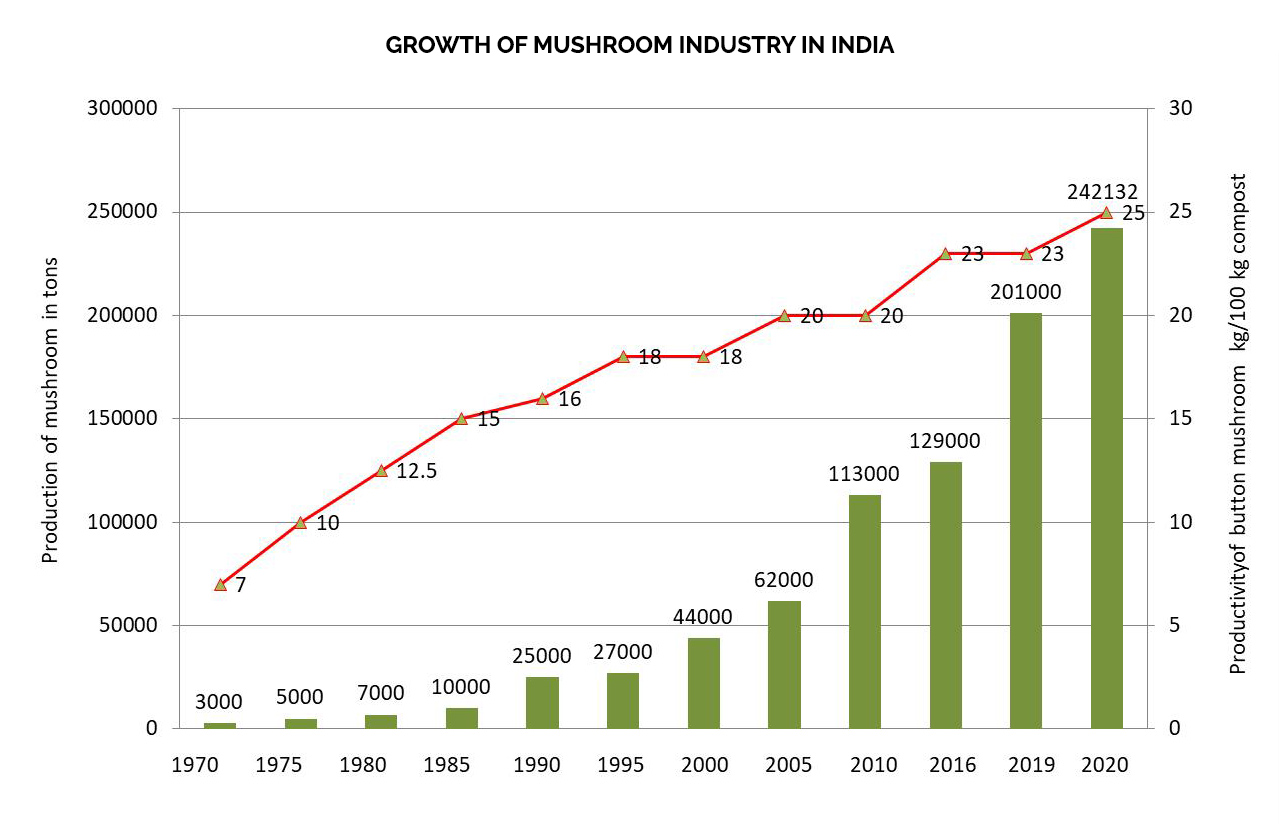

Commercial mushroom farming was introduced in India in late 1960’s & 1970’s, when European specialists like E. F Mantel, W. A. Hayes & J. Tunny, collaborated with Indian agriculturists in North India. Till 1980’s hardly any growth was seen.

In the past 2 decades there has been a shift towards commercial mushroom cultivation, as many working professionals and youngsters alike have gravitated towards mushroom consumption in a variety of local Indian cuisine.

While the most obvious use of mushrooms is seen in the home consumption in processed foods, hotels, and lately in Nutraceuticals, mushrooms are gaining popularity. Year on year average 10% growth is foreseen. Though lately competition within the companies has been fierce, leading to reduce in prices by 10%compared to pre-Covid times. Along with increase in cost of production to approximately 10% lately, some companies are finding it difficult to run their business.

Our Consumers across 15 cities in Western and Southern India have become aware over the years and look forward for value for money and hence want to buy a quality product. Distributors are important in the chain. Lately some B2B marketing is being tried with superstores. What consumers look for is “white colored mushrooms” available at a reasonable cost and timely daily delivery!

While corporate identity and logo helped in nurturing trust, being a fresh and highly perishable product, packaging accordingly had to be thought of for maximized visibility as well as to promote health benefits among consumers. Our motto says “Creating food through innovation”. We adhere to it and produce quality product through innovation.

It’s an everyday challenge to produce good quality mushrooms 24x7, with in-house controlled growing conditions, logistics with early morning arrivals in the concerned markets across Western and Southern India all 365 days a year! And with good quality available daily within consumer reach, through these consumers, we could create trust in our brand across India. Accordingly we are building production volumes also.