The influence of straw on your composting process

By Geert Lemmers Composting Consultancy B.V.

By Geert Lemmers Composting Consultancy B.V.

Introduction

Straw, horse manure and hay are the raw materials that have the most influence on the mushroom production process. Its structure affects the composting process. Its fibers (i.e. celluloses,

hemicelluloses and lignin) are important carbon sources. The mycelium needs hemicelluloses and lignin for growth during the spawn run and case run phases (vegetative phase). In the so-called generative phase, from pin outgrow to mature mushrooms, celluloses and hemicelluloses are needed. Mushroom substrate has to undergo certain process steps. For the phase I composting process these are the so-called biological and chemical steps. During the phase II process the conversion of ammonia and the creation of selectivity make up the next step. During the phase III composting process the final step is mycelium development. Straw (or horse manure, hay) has a big impact on all these process steps.

Brief description of the composting process

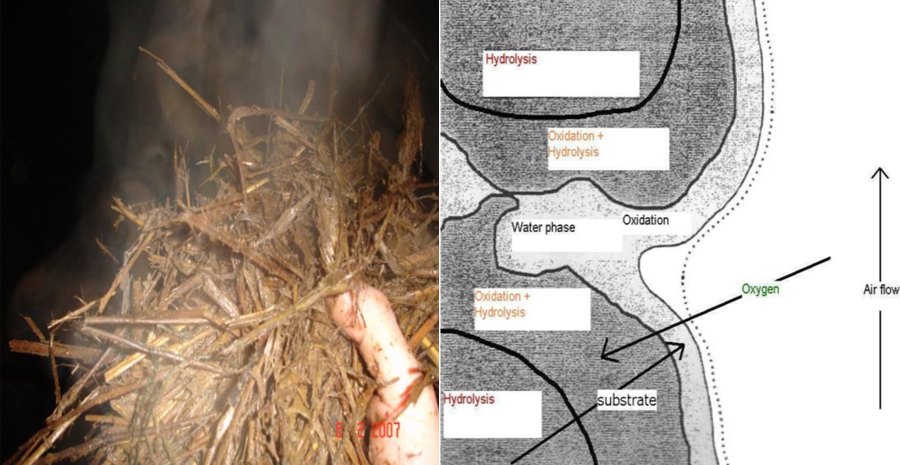

The phase I composting process is crucial in making a good mushroom substrate. We determine quality by looking at color, waxy layer, stickiness and last but not least whether the surface of straw and chicken manure underwent the right phase I processes (brown/black color). Equally important is having the right composting processes (i.e. hydrolysis, fermentation) on the inside of straw and chicken manure particles. In the core of straw and chicken manure particles hydrolyses can only take place when water (i.e. goody water) is absorbed by the inside. The oxygen level in those particles is low. Towards the surface oxygen levels will be higher and fermentation takes place.

On the surface of straw and chicken manure particles (high oxygen levels), oxidation of the hydrolysis and fermentation substances takes place. It is important that there is a balance between the released an oxidized substances. When there are more fermentation substances created than converted by oxidation, your substrate will go anaerobic. Often this situation arises when there is too much free water and/or when there is a poor compost structure. When your substrate is too dry and/or when the water has not been absorbed inside the straw particles, the hydrolyses and fermentation process will be reduced and your pre-wet process is only partly completed. If the process is balanced the compost temperature rises to 70 °C and ammonia is formed (i.e. ammonification process). Ammonia formation occurs at a correct C/N ratio, moisture content and at a temperature between 45 and 70 °C. Now your substrate is ready for the chemical step of the phase I process.

During the chemical part of the composting process, straw cell structures are cracked. This is caused by the high pH and high ammonia levels. Ammonia enhances Maillard reactions and forms the lignin-nitrogen complex in your substrate. The high temperature stimulates the browning. Everything together forms the foundation for a selective and high-productive mushroom substrate.

Keep in mind that every time you turn the compost, it will go through another biological process. In winter periods this biological process is more intense compared to summer periods. The cooling of the substrate while turning is less during warmer periods.

The duration of pre-wetting, the duration of high temperatures, and the number of turns in the phase I process depend on various aspects. These are:

- The quality of your straw (horse manure, or hay),

- The moisture balance,

- The nitrogen content,

- The intensity and quality of the mixing process.

What is structure?

The following factors should be checked when you analyze the straw structure:

- The length of straw,

- The thickness of straw and straws walls,

- Flat or round internodes,

- The brittleness of straw,

- The thickness and strength of the nodes,

- The toughness of straw,

- The amount of fine parts in the straw bale.

Factors that affect straw structure

Variety and climate

Wetter and cooler climates tend to produce more voluminous and longer straw compared to hot and dry climates. Irrigated straw in a dry climate is long, tough and very difficult to dewax and pre-wet. Usually wheat straw is shorter compared to barley and rye straw. Barley straw is long but soft. Barley straw tends to form balls in the mixing process in case one is not using adequate mixing equipment. These balls of straw do not compost correctly. Sometimes oat straw is used. I do not recommend using it, because it is difficult to compost. The best straw for composting purposes is wheat and rye.

Growing season

The growing season, especially during springtime when the straw biomass develops, determines both straw length and strength. During hot summers more lignin is formed compared to milder/cooler summers.

Plant growth regulators

Plant growth regulators are used to reduce straw length. This reduces the risk of having stalks that bend down once the grain kernels become too heavy. The use of these growth regulators affect the structure of straw. Rainfall and temperature during spring determine whether these growth regulators are applied or not.

Harvesting

During harvesting the weather has a big impact on straw structure and how the straw absorbs and retains water during the composting process. Water absorption capacity is very much influenced by the waxy layer, the toughness, and the length of straw. For harvesting most farmers use rotary combines. Under dry circumstances the straw will be more brittle. Under such circumstances these harvesting machines have a big impact on the straw structure. Very sunny weather during harvesting and baling makes the straw difficult to compost. The water absorption of that straw will be less. This creates more free water during the composting process. This causes higher risks of anaerobicity, especially at the start of the composting process. Higher levels of free water result in a slower composting process.

Type of straw bales

Straw baled during very sunny and hot weather will be more brittle. The baling itself has a big impact on both straw structure and the number of fine particles. Nowadays heavier bales are produced in order to save on transportation costs. Heavier bales mean more compression and more compression means flatter and more shattered straw. Round bales leave the straw longer than square bales. Nowadays fewer round bales are used because the handling is more difficult. Composters who dunk their bales during the pre-wetting process should keep in mind that compacted straw bales are more difficult to wet. The same applies to straw that has been baled during dry and sunny weather. Longer or double dunking (i.e. wetting) can help you improve your pre-wetting process. The best straw for composting purposes is straw that is baled dry (less than 15% moisture content), baled tight and which looks a bit dull.

Storage of the straw

When straw is harvested dry, baled and stacked well, it can be stored easily for more than a year. In a very good straw year you often see that straw, stored for 6 to up to 16 months, composts well and gives good mushroom yields. It is very important to have a good system in place for managing the straw storage in the field. It is important to know what type of straw is stored where. This makes it easier to make and stick to a consistent straw blend. This is the first step in making a consistent mushroom substrate.

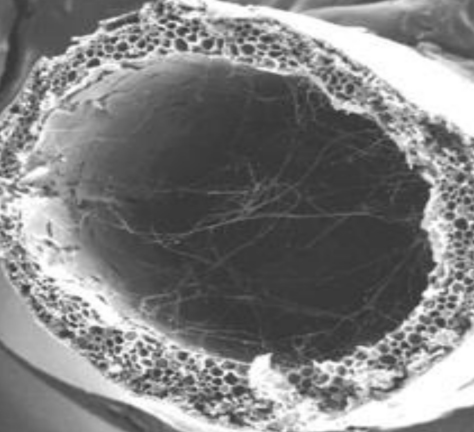

Matrix between lignin, celluloses and hemicelluloses and water absorption/ structure

These three structural fibers have an impact on straw structure and straw toughness. When changing from old to new season straw, one can often see that the hemicelluloses, nitrogen and moisture content shows only minor deviations. But, once you look to the composting process, sometimes relative big steps need to be taken in order to make a productive substrate. I have always wondered what else besides fiber content might impact this topic. Can the straw cell size be smaller or bigger? Can celluloses be more complex? Is the lignin more difficult to break down?

The so called crystallinity Index of celluloses (C.I.) is seen as an important analysis tool for straw that is used for cattle feed or bioethanol purposes. Can the C.I. index indicate how easy the mycelium breaks down the celluloses during first, second and third flush?

Can the ratio of lignin building blocks Synapyl alcohol (S), Conferyl alcohol (G), and Coumaryl alcohol (H) have an impact on how straw maintains its structure during composting and growing? Or does it influence how water is absorbed? Does it influence how celluloses becomes available for mushroom outgrow? Or does the thickness of the epidermis and cuticle of straw have an impact on water absorption and the composting process? After all these years we still do not know exactly how the process of mycelium growth and mushroom development works.

Practical information concerning straw handling

Managing and knowing your straw is the first step in making a consistent and productive mushroom substrate. In the field I work with some sort of check list which helps me determine the straw quality throughout a season. It also tells me how and when I need to adjust the composting process.

- Before change to new straw, try to have an old straw stock for about two to three months. Use only good straw to store for a period longer than 12 months.

- Make sure the straw bales are properly stacked. The storage location, either in the field or at the composting site, is irrelevant. Most important is that there is logic which works well for you,

- Straw baled during very hot and dry weather periods needs to be stored outside for at least six months before it can be used for composting,

- Make sure that the straw stock is managed properly. Use the wettest bales first and make a thorough blend between top and bottom bales. This becomes more important towards the end of the season,

- Make a straw blend. Often there are quality differences (such as structure and moisture) between different straw stacks. Make a blend that can be maintained throughout a longer period of time,

- Speak regularly with your straw suppliers during the growing season. Discuss volumes and straw growing related items,

- Monitor the harvesting and baling season closely. If possible try to get some control on the baling process. Don’t bale during the day when it is hot and sunny weather. Try to postpone the baling towards the evening, night or early morning,

- Analyze straw coming from different suppliers from different regions. Analyze moisture and nitrogen contents. Visual features are important too. Check for structure, waxy layer, quantity of fine parts, and how easily the straw tears up,

- Depending on how much old season straw there is left, make one test batch with the new season straw inbetween. Compare differences in moisture, nitrogen, how it composts, and how it loses water during the phase II and phase III composting processes,

- If possible, start using some new straw in your mix. Start with 25%. Depending on the old season straw availability, increase with 25% at a time. The first 25% has little or no impact. Moving from 25 to 50% will show a difference. Align moisture management, the duration of the phase I composting process, the number of turns, and nitrogen application during the transition period,

- Some compost yards go from old to new season straw in one or two steps. Monitor accurately the moisture management, the nitrogen application, and the duration of the phase I composting process,

- In case the substrate stays too green (i.e. low bulk density, quick ammonia clearing, high C/N ratio), increase the nitrogen quantity, increase the moisture KPI’s throughout the process, increase the pre-wet time, and increase the number of (bunker) turns,

- In case the substrate gets to soft, decrease the nitrogen quantity, decrease moisture KPI’s, reduce pre-wet time, and reduce the number of turns,

- Have your own composting plan. You need to know what steps should be taken and what should be adjusted when the new season straw enters the composting processes.